Drill pipes are critical components that enable efficient drilling performance and play an irreplaceable role across all types of drilling operations. They are typically manufactured from durable alloy steel and undergo specialized heat-treatment processes to enhance tensile, compressive, and torsional resistance, ensuring reliable operation under demanding geological conditions.

For the joints, Cr-Mo alloy steel is commonly used. After heat treatment and surface nitriding, the joints gain improved wear and corrosion resistance. The pipe body and joints are joined using advanced welding technology, followed by weld heat treatment and 100% non-destructive testing to ensure a secure, leak-tight connection.

SPM currently offers four types of drill pipes: deep hole drill pipes, mining drill pipes, anchor drill pipes, and double wall drill pipes.

| OD | Wall thickness, mm | Thread type | Length range, mm | |

| inch | mm | |||

| 3 1/2 | 89 | 6.5 | NC26 | 1000-9140 |

| 4 | 102 | 6.5 | NC31 | 1000-9140 |

| 4 1/2 | 114 | 8.5 | NC35 | 1000-9140 |

| 5 | 127 | 8.5 | NC38 | 1000-9140 |

- Joints manufactured from Cr-Mo alloy steel with surface nitriding.

- Pipe body and joints welded as one through friction welding, with post-weld heat treatment.

- Non-destructive testing on all welds and joints.

| OD | Wall thickness, mm | Thread type | Length range, mm | |

| inch | mm | |||

| 2.5 | 63 | 4.5 | DZ50 | 1000-2000 |

| 3 | 76 | 4.5 | 2 3/8 Reg API | 1000-3000 |

| 3 1/2 | 89 | 4.5/9/13 | 2 3/8 IF API | 1000-9140 |

| 4 | 102 | 6.5/9/19 | 2 7/8 Reg API | 1000-9140 |

| 4 1/2 | 114 | 8.5/11/16 | 3 1/2 Reg API | 1000-9140 |

| 5 | 127 | 8.5 /13/16 | 3 1/2 Reg API or 3 1/2 BECO | 1000-9140 |

| 5.5 | 140 | 11/16 | 3 1/2 BECO | 6300-9140 |

| 6.25 | 159 | 13 /19 | 4 BECO | 6300-10670 |

| 7 | 178 | 13/19/25 | 4 1/2 BECO | 7620-10670 |

- Joint torsional strength increased by 20–30%.

- Joint inner diameter 10% larger than that of standard drill pipes.

- Improved deformation resistance for extended service life.

- Enhanced thread protection to prevent premature corrosion from drilling fluids.

| OD | Wall thickness, mm | Thread type | Length range, mm | |

| inch | mm | |||

| 2 7/8 | 73 | 8 | NC26 | 1000-3000 |

| 3 1/2 | 89 | 10 | NC31 | 1000-3000 |

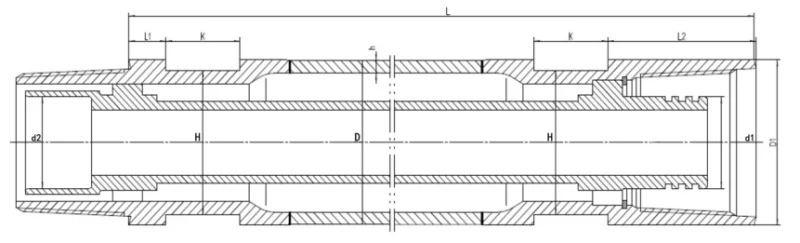

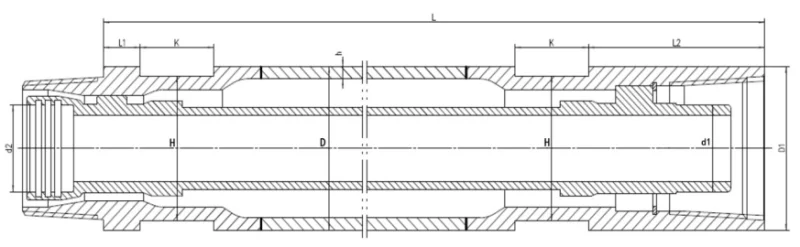

| No. | D, mm | h, mm | Thread type | D1, mm | d1, mm | d2, mm | H, mm | K, mm | L1, mm | L2, mm | L, mm |

| 1 | Ø89 | 6.5 | 3 1/2' Remet | Ø94 | Ø50 | Ø50 | 82 | 40 | 33 | 118 | 1500 |

| 2 | 3000 | ||||||||||

| 3 | Ø102 | 8 | 4' Remet | Ø103 | Ø57 | Ø57.2 | 90 | 50 | 25 | 100 | 1500 |

| 4 | 3000 | ||||||||||

| 5 | 6000 | ||||||||||

| 6 | Ø114 | 8.5 | 4 1/2' Remet | Ø118 | Ø63.5 | Ø63.5 | 100 | 50 | 25 | 145 | 1500 |

| 7 | 3000 | ||||||||||

| 8 | 6000 |

| No. | D, mm | h, mm | Thread type | D1, mm | d1, mm | d2, mm | H, mm | K, mm | L1, mm | L2, mm | L, mm |

| 9 | Ø102 | 8 | 4' Metzke | Ø102 | Ø54 | Ø54 | 90 | 50 | 25 | 120 | 1500 |

| 10 | 3000 | ||||||||||

| 11 | 6000 | ||||||||||

| 12 | Ø114 | 8.5 | 4 1/2' Metzke | Ø114 | Ø57.5 | Ø57.5 | 100 | 50 | 20 | 130 | 1500 |

| 13 | 3000 | ||||||||||

| 14 | 6000 |