SPM’s factory covers over 7,000 m² and benefits from excellent transportation access, facilitating both raw material intake and product distribution.

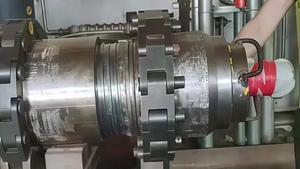

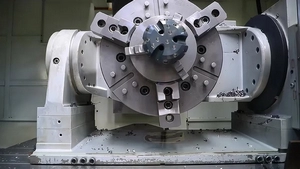

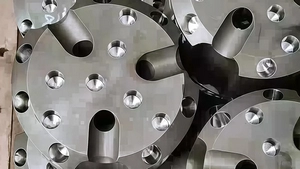

Years of development have established a complete production system, implementing full CNC machining for all components and special process control for key operations, ensuring high product quality and reliability from the source.

The production workflow employs full-process CNC machining. Within the 7000 m² production facility, all critical components are precisely crafted on advanced CNC machines, achieving micrometer-level accuracy. Core products such as DTH hammers and drill bits undergo specialized in-house processing methods. For example, in reverse circulation drilling rigs, special polishing and surface treatment of internal flow channels reduce fluid resistance by over 15%, significantly improving drilling efficiency. Production processes are tightly integrated, and every stage, from raw material receipt to finished product, is managed digitally through an ERP system, ensuring quality control.

SPM implements three-stage inspection with centralized control system:

- Raw materials are precisely analyzed with a spectrometer upon arrival to ensure steel composition meets high-strength and wear-resistant standards.

- During production, operators conduct self-inspections at each step, while quality inspectors perform specialized checks to prevent cumulative errors.

- Finished products undergo 100% performance testing simulating complex conditions such as mining and water well operations, verifying key parameters like hammer impact frequency and drill bit wear resistance.

- Real-time monitoring and analysis of production quality fluctuations maintain defective product rates below 0.3%.

This comprehensive production and quality control system enables SPM to consistently deliver efficient performance, reliable drilling equipment that earns customer trust.

-

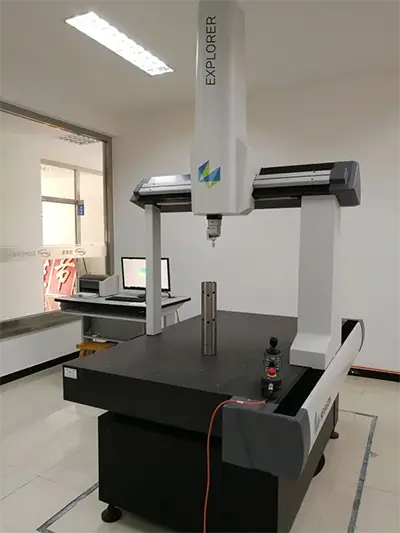

Coordinate measuring machine

Coordinate measuring machine

-

Ultrasonic flaw detector

Ultrasonic flaw detector -

Leeb hardness tester

Leeb hardness tester -

Carbon content analyzer (CCA)

Carbon content analyzer (CCA) -

Portable spectrometer

Portable spectrometer -

Metallographic sample mounting machine

Metallographic sample mounting machine -

Microhardness tester

Microhardness tester