Reverse Circulation DTH Drilling Tools

Reverse circulation DTH drilling is a high-efficiency mineral sampling method powered by compressed air, typically utilized with specialized RC rigs, dual-wall drill pipes, and sampling discharge systems.

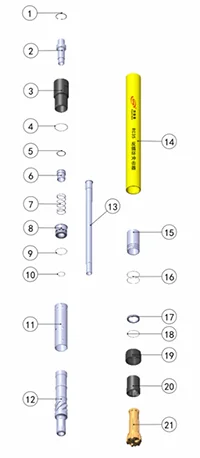

As the core component of this drilling system, our RC DTH drilling tools consist of a RC DTH hammer, dual-wall drill pipes and drill bits. During operation, the hammer delivers high-frequency impacts to fracture the rock while creating a stable suction effect at the bit face. This ensures that cuttings and samples are instantly transported through the inner tube to the surface. This process guarantees continuous sampling, minimal contamination, and high sample representativeness, making it an ideal choice for geological exploration and mineral sampling.

- Compressed air and the returning fluid are transported within a sealed dual-wall drill string, avoiding contact with the borehole walls and preventing scouring, greatly reducing the risk of downhole accidents and maintaining borehole stability. It is especially effective in complex or loss-prone formations.

- Rock and mineral samples are carried through the central channel directly to the surface without touching the borehole walls, ensuring high sampling rates and contamination-free samples.

- Cuttings are discharged through the central channel to designated collection points, enabling centralized handling, precise geological layer identification, dust prevention, and reduced environmental contamination. This also improves working conditions, prolongs equipment service life, and increases rig uptime.

Primarily suitable for medium to high hardness rock formations such as granite, basalt, and limestone. Widely applied in mining, water well drilling, geological exploration, and tunnel engineering. Particularly advantageous for projects requiring high drilling depth, verticality, and efficiency.

| Model (SPM P/N) |

Hammer OD, mm |

Hammer length (W/O bit), mm |

Drilling dia., mm | Sample tube dia., mm |

Working pressure, MPa |

Air consumption, m³/min |

Top sub thread | Weight, kg |

| |

90 | 991 | 95-110 | 30 | 0.7-2.1 | 4.2-14 | T 2 3/8 Box | 30 |

| |

105 | 1038 | 115-130 | 36 | 0.7-2.1 | 4.5-20 | T 2 7/8 Box | 41 |

| |

116 | 975 | 127-140 | 30 | 0.7-2.4 | 6-20.6 | T 3 1/2 Box | 48 |

| |

124 | 1038 | 133-152 | 36 | 0.7-2.4 | 6-21.5 | T 4 Box | 60.5 |

| |

154 | 1040 | 159-203 | 61 | 0.7-2.4 | 7-25.5 | T 4 5/8 Box | 89 |

| |

190 | 1254 | 203-241 | 61 | 0.7-2.4 | 10-30.5 | T 6 Box | 167 |

| |

230 | 1345 | 241-311 | 76 | 0.7-2.4 | 15-34 | T 6 5/8 Box | 263 |

| |

285 | 1410 | 311-350 | 85 | 0.7-2.4 | 20.37.8 | T 8 5/8 Box | 423.5 |

| |

330 | 1520 | 355-410 | 98 | 0.7-2.4 | 23-54.5 | M 10 3/4 Box | 921 |

| |

394 | 1807 | 406-508 | 110 | 0.7-2.4 | 27-91.4 | M 10 3/5 Box | 1308 |