DTH Hammers (Medium Air Pressure)

Down-the-hole hammers for rock drilling in medium-hard to hard rock formations with medium air pressureSPM medium air pressure DTH hammers feature an internal structure designed according to advanced rock drilling theory, ensuring efficient energy transfer, faster drilling speed, and lower air consumption. They are widely used in geotechnical engineering for drilling medium-hard to hard rocks and other tough formations that are difficult to drill.

In practical use, medium air pressure DTH hammers are recommended for drilling medium-hard to hard rocks in geotechnical engineering. Typical applications include mining, quarrying, road construction, blasting hole drilling, landslide protection, dam foundation reinforcement, anchoring, geothermal energy wells, water wells, hydrological wells, and other engineering projects.

| Model | Top sub connection thread |

Wrench flat, mm |

Hammer OD, mm |

Length (W/O bit), mm |

Weight (W/O bit), kg |

Bit shank | Hole range mm |

Piston weight, kg |

Recommended rotation speed, rpm |

Feed force, kg |

Air consumption, m³/min |

|||||

| 5bar | 10bar | 12bar | 14bar | 15bar | 17bar | |||||||||||

| Special M42x10x1.5 | 48 | 58 | 715 | 9.5 | SPM825 | 65-70 | 2 | 35-60 | 390-630 | 2.5 | 3 | 4 | - | - | - | |

| DZ50 Box | 47 | 67 | 808 | 15 | SPM830 | 75-85 | 3.4 | 35-60 | 450-780 | 3 | 3.5 | 5 | - | - | - | |

| |

Special M48x10x3 | 60 | 80 | 822 | 22.5 | SPM930 | 90-130 | 4.7 | 35-60 | 550-1200 | 3.5 | 4 | 6.5 | - | - | - |

| |

Special 48x10x3 | 60 | 82 | 782 | 21 | SPM930 | 90-130 | 4.8 | 35-60 | 550-1170 | - | 6 | - | 8 | - | - |

| |

API 2-3/8 REG Box | 75 | 98 | 910 | 35 | SPM940 | 110-135 | 7.4 | 35-60 | 660-1250 | - | 5.5 | - | - | 9 | - |

| |

API 2-3/8 REG Pin | 75 | 126 | 970 | 64 | SPM950 | 138-152 | 12 | 35-60 | 850-1380 | - | 7.5 | - | - | 12 | - |

| |

API 3-1/2 REG Pin | 101 | 148 | 1130 | 100 | SPM960 | 165-203 | 23 | 30-60 | 990-1850 | - | 9 | - | - | - | 15 |

| |

API 4-1/2 REG Pin | 150 | 182 | 1260 | 180 | SPM980 | 203-254 | 43 | 30-50 | 1250-2300 | - | 13 | - | - | - | 26 |

| |

API 4-1/2 REG Pin | 150 | 224 | 1260 | 260 | SPM9100 | 241-311 | 33 | 20-40 | 1500-2800 | - | 14 | - | - | - | 26 |

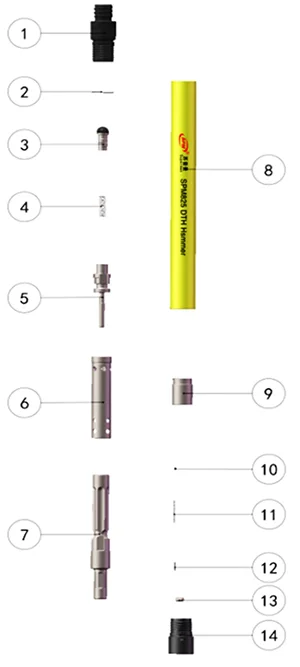

The medium air pressure DTH hammer is illustrated using the SPM825 model as an example (internal structure may vary slightly for other models).

| No. | Product name | Product No. | Qty |

| 1 | Backhead | 825001000 | 1 |

| 2 | O ring | 825002300 | 1 |

| 3 | Check valve | 82004000 | 1 |

| 4 | Spring | 76002300 | 1 |

| 5 | Distributor | 825005000 | 1 |

| 6 | Cylinder | 825006000 | 1 |

| 7 | Piston | 825007000 | 1 |

| 8 | Casing | 825008000 | 1 |

| 9 | Bearing | 825009000 | 1 |

| 10 | Rubber plugs | 80016300 | 1 |

| 11 | Spring | 80016300 | 1 |

| 12 | Pin | 80017300 | 1 |

| 13 | Key | 65018300 | 1 |

| 14 | Chuck | 825014000 | 1 |