DHD Series DTH Bits

Down-the-hole drill bits for mining, quarrying and exploration drilling

SPM offers a complete range of DTH bits, precisely tailored for various drilling scenarios. Products feature large front flushing grooves combined with waist-flow designs to accelerate airflow, reduce wear, and enhance durability. Durable alloy steel is precision-machined and surface stress-treated, paired with highly wear-resistant alloy buttons, ensuring enhanced longevity and operational efficiency.

The DHD series bits comply with industry-standard specifications and are fully compatible with other brand DHD drill tools of the same model, offering flexible operational solutions for diverse equipment configurations. The following basic bit types are optimized for different rock characteristics and working conditions.

-

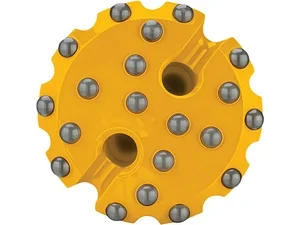

Convex (Ballistic Button) Design

Features a skirt structure with alloy buttons for improved cuttings removal, faster penetration in clay layers, and reduced regrinding wear. Dual-row outer teeth fit drill bits ≥178 mm (7 inches). Suitable for hard, abrasive rocks and various formations, especially fractured or loose strata.

Typical formations: Granite (220 MPa / 32,000 psi), Hard Limestone (200 MPa / 29,000 psi), Basalt (300 MPa / 43,500 psi)

-

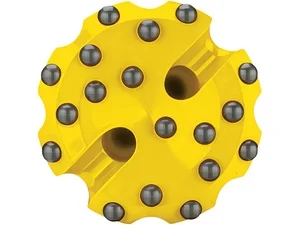

Flat (Spherical Button) Design

Optimized for abrasive, very hard rocks, suitable for all formations, particularly high-silica abrasive layers.

Typical formations: Granite (220 MPa / 32,000 psi), Hard Limestone (200 MPa / 29,000 psi), Basalt (300 MPa / 43,500 psi)

-

Flat-Edge Ballistic Button Design

Combines spherical and flat ballistic buttons to balance wear resistance and rock-breaking capability, suitable for medium-hard and abrasive rocks, optimized for high-productivity drilling.

Typical formations: Granite (220 MPa / 32,000 psi), Hard Limestone (200 MPa / 29,000 psi), Basalt (300 MPa / 43,500 psi)

-

Concave Design

Significantly improves borehole verticality and reduces deviation. Suitable for hard, abrasive rocks and all formations, especially fractured/loose strata and projects requiring high vertical accuracy, fitting drill bits >178 mm (7 inches).

Typical formations: Granite (220 MPa / 32,000 psi), Hard Limestone (200 MPa / 29,000 psi), Basalt (300 MPa / 43,500 psi)

| SPM P/N |

Diameter, mm | Button configuration (No. x dia., mm) |

Gauge angle, ° | Flushing holes | Approx. weight, kg | |||||

| Outer | Inner | Front | Cone | Outer | Inner | Cone | ||||

| Flat face-spherical buttons | ||||||||||

| 335-90Q | 90 | 8x13 | 7x12 | 35 | 2 | 5.8 | ||||

| 335-95Q | 95 | 8x14 | 7x12 | 35 | 2 | 5.9 | ||||

| 335-100Q | 100 | 8x14 | 7x13 | 35 | 2 | 6.1 | ||||

| 335-105Q | 105 | 8x14 | 8x13 | 35 | 2 | 6.3 | ||||

| Convex face-ballistic buttons | ||||||||||

| 335-90D | 90 | 6x13 | 3x12 | 2x12 | 45 | 20 | 2 | 5.8 | ||

| 335-95D | 95 | 6x14 | 3x12 | 3x12 | 45 | 20 | 2 | 5.9 | ||

| 335-100D | 100 | 6x14 | 3x13 | 4x12 | 35 | 20 | 2 | 6.1 | ||

| 335-105D | 105 | 6x14 | 3x13 | 4x12 | 35 | 20 | 2 | 6.3 | ||

| Flat face-gauge spherical & center ballistic buttons | ||||||||||

| 335-90S | 90 | 8x13 | 7x12 | 35 | 2 | 5.8 | ||||

| 335-95S | 95 | 8x14 | 7x12 | 35 | 2 | 5.9 | ||||

| 335-100S | 100 | 8x14 | 7x13 | 35 | 2 | 6.1 | ||||

| 335-105S | 105 | 8x14 | 8x13 | 35 | 2 | 6.3 | ||||

| Configuration: matched shank SPM335-19 | ||||||||||

| SPM P/N | Diameter, mm | Button configuration (No. x dia., mm) |

Gauge angle, ° | Flushing holes | Approx. weight, kg | |||||

| Outer | Inner | Front | Cone | Outer | Inner | Cone | ||||

| Flat face-spherical buttons | ||||||||||

| 340-105Q | 107 | 8x14 | 0 | 7x13 | 0 | 35 | 0 | 0 | 2 | 8.6 |

| 340-115Q | 115 | 8x14 | 0 | 7x13 | 0 | 35 | 0 | 0 | 2 | 8.8 |

| 340-120Q | 120 | 8x14 | 0 | 8x13 | 0 | 35 | 0 | 0 | 2 | 9 |

| 340-130Q | 130 | 8x14 | 0 | 8x13 | 0 | 35 | 0 | 0 | 2 | 9.6 |

| Convex face-ballistic buttons | ||||||||||

| 340-105D | 107 | 7x14 | 4x13 | 2x13 | 0 | 35 | 15 | 0 | 2 | 8.6 |

| 340-115D | 115 | 7x14 | 4x13 | 2x13 | 0 | 35 | 15 | 0 | 2 | 8.8 |

| 340-120D | 120 | 8x14 | 4x13 | 3x13 | 0 | 35 | 15 | 0 | 2 | 9 |

| 340-130D | 130 | 8x14 | 4x13 | 3x13 | 0 | 35 | 15 | 0 | 2 | 9.6 |

| Flat face-gauge spherical & center ballistic buttons | ||||||||||

| 340-105S | 107 | 8x14 | 0 | 7x13 | 0 | 35 | 0 | 0 | 2 | 8.6 |

| 340-115S | 115 | 8x14 | 0 | 7x13 | 0 | 35 | 0 | 0 | 2 | 8.8 |

| 340-120S | 120 | 8x14 | 0 | 8x13 | 0 | 35 | 0 | 0 | 2 | 9 |

| 340-130S | 130 | 8x14 | 0 | 8x13 | 0 | 35 | 0 | 0 | 2 | 9.6 |

| Configuration: matched shank SPM340-18 | ||||||||||

| SPM P/N | Diameter, mm | Button configuration (No. x dia., mm) |

Gauge angle, ° | Flushing holes | Approx. weight, kg | |||||

| Outer | Inner | Front | Cone | Outer | Inner | Cone | ||||

| Flat face-spherical buttons | ||||||||||

| 350-130Q | 130 | 7x16 | 0 | 7x14 | 0 | 35 | 0 | 0 | 2 | 15.7 |

| 350-140Q | 140 | 7x16 | 0 | 7x14 | 0 | 35 | 0 | 0 | 2 | 16 |

| 350-152Q | 152 | 8x16 | 0 | 8x14 | 0 | 35 | 0 | 0 | 2 | 17.8 |

| 350-165Q | 165 | 8x16 | 0 | 9x16 | 0 | 35 | 0 | 0 | 2 | 18.2 |

| 350-178Q | 178 | 8x16 | 0 | 9x16 | 0 | 35 | 0 | 0 | 2 | 19.8 |

| Convex face-ballistic buttons | ||||||||||

| 350-130D | 130 | 7x16 | 4x14 | 3x14 | 0 | 35 | 15 | 0 | 2 | 15.7 |

| 350-140D | 140 | 7x16 | 4x14 | 3x14 | 0 | 35 | 15 | 0 | 2 | 16 |

| 350-152D | 152 | 8x16 | 4x14 | 4x14 | 0 | 35 | 15 | 0 | 2 | 17.8 |

| 350-165D | 165 | 8x16 | 4x14 | 5x14 | 0 | 35 | 15 | 0 | 2 | 18.2 |

| 350-178D | 178 | 8x16 | 4x16 | 5x16 | 0 | 35 | 15 | 0 | 2 | 19.6 |

| Flat face-gauge spherical & center ballistic buttons | ||||||||||

| 350-130Q | 130 | 7x16 | 0 | 7x14 | 0 | 35 | 0 | 0 | 2 | 15.7 |

| 350-140Q | 140 | 7x16 | 0 | 7x14 | 0 | 35 | 0 | 0 | 2 | 16 |

| 350-152Q | 152 | 8x16 | 0 | 8x14 | 0 | 35 | 0 | 0 | 2 | 17.8 |

| 350-165Q | 165 | 8x16 | 0 | 9x16 | 0 | 35 | 0 | 0 | 2 | 18.2 |

| 350-178Q | 178 | 8x16 | 0 | 9x16 | 0 | 35 | 0 | 0 | 2 | 19.8 |

| Configuration: matched shank SPM350-18 | ||||||||||

| SPM P/N | Diameter, mm | Button configuration (No. x dia., mm) |

Gauge angle, ° | Flushing holes | Approx. weight, kg | |||||

| Outer | Inner | Front | Cone | Outer | Inner | Cone | ||||

| Flat face-spherical buttons | ||||||||||

| 360-152Q | 152 | 8x16 | 0 | 11x14 | 0 | 35 | 0 | 0 | 2 | 23.5 |

| 360-165Q | 165 | 8x16 | 0 | 10x16 | 0 | 35 | 0 | 0 | 2 | 25 |

| 360-171Q | 171 | 9x16 | 0 | 10x16 | 0 | 35 | 0 | 0 | 3 | 25.8 |

| 360-178Q | 178 | 8x16 | 0 | 11x16 | 0 | 35 | 0 | 0 | 2 | 27 |

| 360-194Q | 194 | 9x16 | 0 | 12x16 | 0 | 35 | 0 | 0 | 3 | 29 |

| Convex face-ballistic buttons | ||||||||||

| 360-165Q | 165 | 8x16 | 4x16 | 6x16 | 0 | 35 | 15 | 0 | 2 | 25 |

| 360-171Q | 171 | 9x16 | 6x16 | 4x16 | 0 | 35 | 15 | 0 | 3 | 25.8 |

| 360-178Q | 178 | 8x16 | 4x16 | 6x16 | 0 | 35 | 15 | 0 | 2 | 27 |

| 360-194Q | 194 | 9x16 | 6x16 | 6x16 | 0 | 35 | 15 | 0 | 3 | 29 |

| Flat face-gauge spherical & center ballistic buttons | ||||||||||

| 360-171A | 171 | 9x16 | 0 | 6x16 | 4x16 | 35 | 0 | -15 | 3 | 25.8 |

| 360-178A | 178 | 8x16 | 0 | 4x16 | 6x16 | 35 | 0 | -15 | 2 | 27 |

| 360-194A | 194 | 9x16 | 0 | 6x16 | 6x16 | 35 | 0 | -15 | 3 | 29 |

| 360-203A | 203 | 9x16 | 0 | 6x16 | 7x16 | 35 | 0 | -15 | 3 | 35 |

| 360-216A | 216 | 9x16 | 0 | 6x16 | 7x16 | 35 | 0 | -15 | 3 | 36 |

| 360-219A | 219 | 9x16 | 0 | 6x16 | 7x16 | 35 | 0 | -15 | 3 | 37.2 |

| 360-230A | 230 | 9x16 | 0 | 9x16 | 7x16 | 35 | 0 | -15 | 3 | 40 |

| 360-241A | 241 | 12x18 | 0 | 9x18 | 8x16 | 35 | 0 | -15 | 3 | 46 |

| 360-254A | 254 | 12x16 | 0 | 9x16 | 8x16 | 35 | 0 | -15 | 3 | 50 |

| 360-300A | 300 | 12x18 | 0 | 12x16 | 9x16 | 35 | 0 | -15 | 0 | 58 |

| 360-305A | 305 | 12x18 | 0 | 12x16 | 9x16 | 35 | 0 | -15 | 3 | 64 |

| Configuration: matched shank SPM360-19 | ||||||||||

| SPM P/N | Diameter, mm | Button configuration (No. x dia., mm) |

Gauge angle, ° | Flushing holes | Approx. weight, kg | |||||

| Outer | Inner | Front | Cone | Outer | Inner | Cone | ||||

| Convex face-ballistic buttons | ||||||||||

| 380-203 | 203 | 8x18 | 0 | 6x18 | 6x16 | 35 | 0 | -15 | 2 | 48 |

| 380-216 | 216 | 9x18 | 0 | 6x18 | 7x16 | 35 | 0 | -15 | 3 | 49 |

| 380-219 | 219 | 9x18 | 0 | 6x18 | 7x16 | 35 | 0 | -15 | 3 | 49.5 |

| 380-230 | 230 | 9x18 | 0 | 6x18 | 8x16 | 35 | 0 | -15 | 3 | 50.8 |

| 380-235 | 235 | 9x18 | 0 | 6x18 | 8x16 | 35 | 0 | -15 | 3 | 51 |

| 380-241 | 241 | 9x18 | 0 | 6x18 | 9x16 | 35 | 0 | -15 | 3 | 51.9 |

| 380-245 | 245 | 9x18 | 0 | 6x18 | 9x16 | 35 | 0 | -15 | 3 | 52.3 |

| 380-254 | 254 | 12x18 | 0 | 6x18 | 14x16 | 35 | 0 | -15 | 3 | 54.5 |

| 380-273 | 273 | 12x18 | 0 | 9x18 | 12x16 | 35 | 0 | -150 | 3 | 73.6 |

| 380-285 | 285 | 12x18 | 0 | 9x18 | 12x16 | 35 | 0 | -15 | 3 | 77.2 |

| 380-300 | 300 | 12x18 | 0 | 9x18 | 12x16 | 35 | 0 | -150 | 3 | 83 |

| 380-305 | 305 | 12x18 | 0 | 9x18 | 12x16 | 35 | 0 | -150 | 3 | 84.6 |

| 380-311 | 311 | 12x18 | 0 | 9x18 | 12x16 | 35 | 0 | -150 | 3 | 85 |

| 380-320 | 320 | 12x18 | 0 | 9x18 | 13x16 | 35 | 0 | -150 | 3 | 88 |

| 380-325 | 325 | 12x18 | 0 | 9x18 | 13x16 | 35 | 0 | -150 | 3 | 89.4 |

| 380-350 | 350 | 16x18 | 0 | 12x18 | 18x16 | 35 | 0 | -150 | 4 | 92 |

| Configuration: matched shank SPM380-19 | ||||||||||

- High-efficiency scenarios: Convex / ballistic button design is preferred, with streamlined structure reducing drilling resistance and significantly increasing penetration speed.

- Harsh formations: For high-hardness, strongly abrasive formations (e.g., quartzite, iron ore), flat spherical button bits offer durable teeth and robust structure, extending service life and reducing replacement frequency.

- Strict quality requirements: For projects requiring precise verticality and smooth boreholes (e.g., pile foundations, anchor drilling), concave designs provide stable drilling trajectory and improved borehole quality.

Bit selection should consider rock hardness, abrasiveness, borehole precision requirements, and equipment compatibility. SPM ensures the equipment’s optimal efficiency and cost-effectiveness across all drilling conditions. Personalized selection guidance is available upon request.