Eccentric Casing System

Casing advancement system for overburden drillingEccentric casing systems are specialized drilling tools used in complex ground conditions such as gravel layers, colluvial deposits, and running sand formations.

They effectively prevent borehole collapse and buried-bit incidents, ensuring drilling quality and construction efficiency.

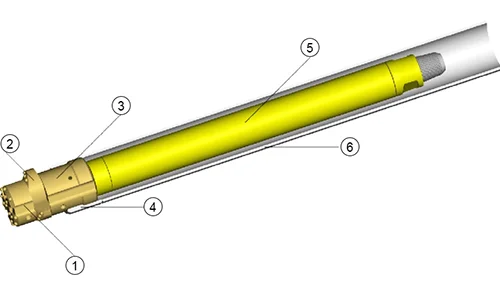

- Pilot bit

- Reaming

- Guide Device

- Casing shoe

- DTH hammer

- Steel casing

An eccentric casing drilling system typically consists of a DTH hammer, eccentric casing drilling assembly, casing shoe, and casing. The eccentric drilling assembly is generally composed of a pilot bit, eccentric reaming bit, centralizer, and locking/unlocking mechanism.

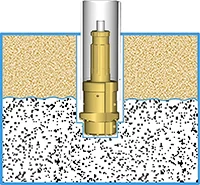

During drilling, the eccentric drilling assembly is lowered through the casing into the casing shoe. When the drill rotates forward, the eccentric bit automatically swings out under bottom-hole friction and creates a borehole larger than the casing’s outer diameter under the DTH hammer’s impact. At the same time, the centralizer shoulder pushes the casing shoe, allowing the casing to advance synchronously with the drilling process to stabilize the borehole.

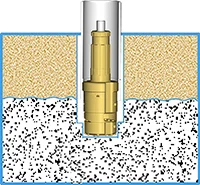

Once the required depth is reached, the drill string is rotated in reverse by a specific angle, causing the eccentric bit to retract. The drilling assembly can then be withdrawn through the casing.

Compared with concentric casing systems, eccentric systems can achieve the same finished borehole diameter using a smaller casing size, reducing material cost while increasing penetration rate and lowering compressor fuel consumption. Concentric systems enter the ground at full diameter, making them more difficult to advance through boulders or hard rock and more prone to casing extraction problems or casing breakage. Eccentric systems avoid these issues, offering a more reliable and efficient solution in challenging ground conditions.

Eccentric casing systems are widely used in drilling operations across hard, broken, loose, and otherwise complex ground formations. Typical applications include geohazard mitigation, hydropower works, urban high-rise foundation support, and road and railway construction.

Before lowering the assembly, inspect all connections and ensure the eccentric bit can rotate freely. During drilling, monitor casing advancement and cuttings discharge; perform strong air flushing every 0.3-0.4 m of penetration. When drilling is complete or the pilot bit needs replacement, first clean the hole, then reverse rotate at low speed to retract the eccentric bit before lifting the assembly.

| Model | Casing OD, mm | Casing min. ID, mm | Reaming diameter, mm | Casing shoe min. ID, mm | Pilot bit max. OD, mm | DTH hammer |

| |

89 | 77 | 98 | 71 | 70 | SPM70 |

| |

108 | 94 | 114 | 86 | 85 | SPM90/90-I |

| |

108 | 94 | 114 | 86 | 85 | SPM335 |

| |

114 | 101 | 118 | 91 | 90 | SPM335 |

| |

127 | 114 | 136 | 103 | 100 | SPM335 |

| |

146 | 130 | 156 | 121 | 120 | SPM110/110- I |

| |

146 | 130 | 156 | 121 | 120 | SPM4.5 |

| |

146 | 130 | 156 | 121 | 120 | SPM340 |

| |

168 | 152 | 185 | 142 | 140 | SPM350/SPMS50 |

| |

178 | 152 | 185 | 146 | 145 | SPM350/SPMS50 |

| |

183 | 152 | 198 | 152 | 150 | SPM350/SPMS50 |

| |

194 | 185 | 210 | 166 | 164 | SPM360/S60 |

| |

219 | 201 | 240 | 187 | 186 | SPM360/S60 |

| |

245 | 221 | 270 | 206 | 203 | SPM380/S80 |

| |

273 | 257 | 300 | 242 | 241 | SPM380/S80 |

| |

325 | 308 | 365 | 286 | 285 | SPM380/S80 |

| |

325 | 308 | 365 | 286 | 285 | SPMS100 |

| |

355 | 327 | 390 | 307 | 305 | SPMS100 |

| |

377 | 347 | 400 | 326 | 325 | SPMS100 |