Reverse Circulation Drilling Rigs

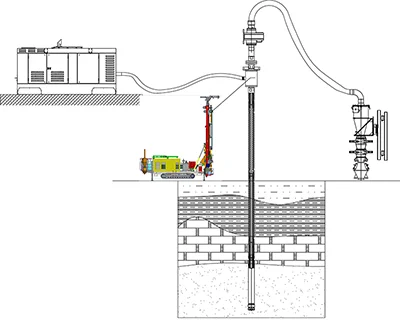

The reverse circulation drilling rig is an efficient, environmentally friendly, and versatile rig mounted on crawler tracks. It uses advanced reverse circulation drilling technology, allowing rock dust to be effectively collected through a dust collector. When air is used as the circulating medium, the system enables water-saving drilling and prevents environmental contamination. Cuttings can also be collected via a cyclone separator for geological sampling and analysis, making it an ideal choice for geological exploration and other deep-hole drilling applications.

The reverse circulation drilling rig can perform compressed-air reverse-circulation drilling across a wide range of ground conditions. Lifting and compensation of the drill mast, drill pipe, rotary and feed systems, outriggers, hoisting operations, and crawler travel are all hydraulically driven, significantly reducing labor intensity while improving drilling efficiency and construction quality.

-

- Rock hardness: F4-F22

- Drill hole diameter: Ø105-400mm

- Drilling depth: 400m

- Power head torque: 10/5KNm

RC500L (up to 400m depth)

RC500L (up to 400m depth)RC drill rigs for drilling depths up to 400m with 105-400mm hole diameters

-

- Rock hardness: F4-F22

- Drill hole diameter: Ø105-550mm

- Drilling depth: 600m

- Power head torque: 18/9KNm

RC800L (up to 600m depth)

RC800L (up to 600m depth)RC drill rigs for drilling depths up to 600m with 105-550mm hole diameters

-

- Rock hardness: F4-F22

- Drill hole diameter: Ø105-800mm

- Drilling depth: 1000m

- Power head torque: 24/12KNm

RC1200L (up to 1000m depth)

RC1200L (up to 1000m depth)RC drill rigs for drilling depths up to 1000m with 105-800mm hole diameters

Reverse circulation drilling technology uses compressed air to drive the RC hammer and bit to break the rock. Rock samples are returned upward through the RC bit, hammer, and drill pipe to the cyclone, where the sample separator removes cuttings from the air-water mixture. The collected samples are then used for geological analysis. This drilling method is known as reverse circulation (RC) drilling.

- High sampling rate

- Contamination-free samples

- High drilling efficiency

- Accurate strata identification

- Easy operation

- Simple drilling process

- No water required

- Supports multi-angle drilling