SPM-A Series Tubeless DTH Hammer (without Foot Valve)

Valveless down-the-hole hammers for rock drilling in hard to very hard rock formations with high air pressure

SPM-A series tubeless high-pressure DTH hammers are core drilling components for the mining and construction industries, designed for complex geological conditions to enhance drilling efficiency and quality. These hammers deliver stable operation and high single-impact energy, allowing effective penetration of hard rock while maintaining low air consumption and extended service life, reducing operational and replacement costs. The strong air-jet system enables efficient cuttings removal, and the hardened wear-resistant outer sleeve can be reversed to further extend replacement intervals.

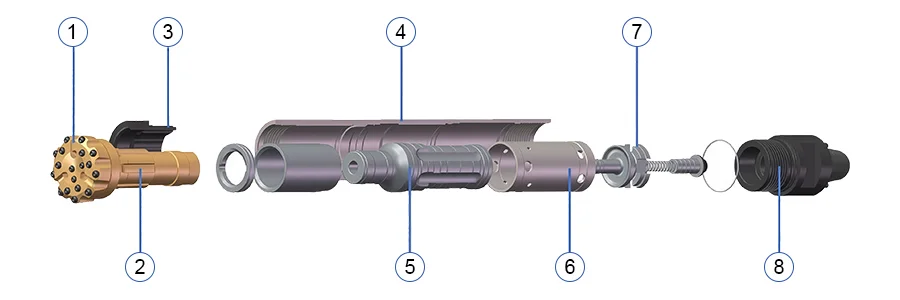

- Optimized bit head: the button teeth with properly arranged flushing holes provide high drilling efficiency. Multiple head types and button tooth structures are available based on rock conditions.

- Robust shank: Made from specialized drill steel with unique heat treatment to extend service life and improve energy transfer efficiency.

- Convenient front connection: Multi-start threaded design with advanced surface treatment enables easier bit replacement.

- Wear-resistant outer sleeve: Constructed from high-quality alloy steel with internal and external surface hardening, providing a 20-30% longer service life.

- Optimized overall structure: Enhances durability, ensures smooth air operation, efficient energy transfer, and improved operational performance.

- Durable cylinder: Advanced wear-resistant and hardened internal surface extends lifespan and reduces pressure loss.

- New air distributor: Valve-free air distribution structure allows adaptable air-flow adjustments to match varying rock conditions.

- Practical rear connection: Standard API threads with optional button tooth structure to meet different operational requirements.

Adjustable air plug: Allows operators to adjust air volume for cuttings removal according to rock hardness, abrasiveness, ensuring optimal cuttings removal and enhanced drilling efficiency.

The hammer is suitable for drilling blast holes in mining, slope protection and anchoring holes in road construction, and drilling geothermal, hydrological, and water well boreholes in energy and civil projects. Its tubeless design prevents hammer head damage caused by thermal expansion or contraction, ensuring reliable performance during transport and operation, supporting infrastructure construction and resource development projects.

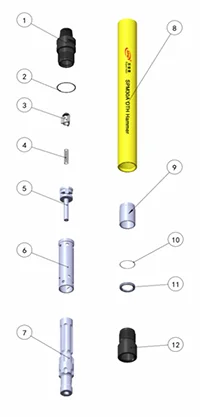

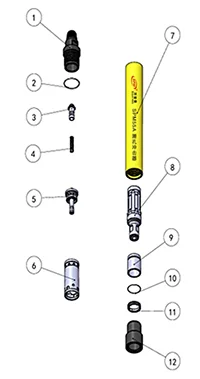

- Top sub

- Top sub with o ring

- Check valve dart

- Check valve dart spring

- Rigid valves

- Internal cylinder

- Piston

- Piston case

- Guide sleeve

- Guide sleeve with o ring

- Bit retainer ring

- Driver sub

Technical Parameters

| Parameter | Specifications | |

| Top sub connection | DZ50 Pin | |

| Hammer length (W/O bit), mm | 825 | |

| Hammer OD, mm | Ø71 | |

| Weight (W/O bit), kg | 17.2 | |

| Wrench flat, mm | 55 | |

| Piston weight, kg | 3.9 | |

| Bit shank | CWG76 | |

| Bit size range, mm | 80-85 | |

| Recommended rotation speed, rpm | 25-40 | |

| Feed force, kg | 480-770 | |

| Air consumption, m³/min | @10bar | 3 |

| @14bar | 4.1 | |

| @17bar | 7 | |

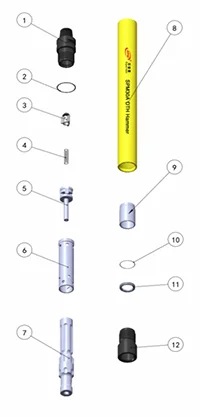

- Top sub

- Top sub with oring

- Check valve dart

- Check valve dart spring

- Rigid valves

- Internal cylinder

- Piston

- Piston case

- Guide sleeve

- Guide sleeve with oring

- Bit retainer ring

- Driver sub

Technical Parameters

| Parameter | Specifications | |

| Top sub connection | DZ50 Pin | |

| Hammer length (W/O bit), mm | 866 | |

| Hammer OD, mm | Ø71 | |

| Weight (W/O bit), kg | 17 | |

| Wrench flat, mm | 55 | |

| Piston weight, kg | 3.9 | |

| Bit shank | SPM30A | |

| Bit size range, mm | 80-85 | |

| Recommended rotation speed, rpm | 25-40 | |

| Feed force, kg | 480-770 | |

| Air consumption, m³/min | @10bar | 3 |

| @14bar | 4.1 | |

| @17bar | 7 | |

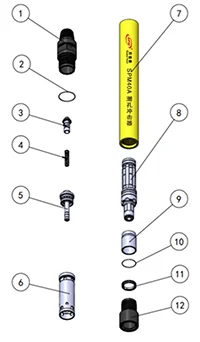

- Top sub

- Top sub with oring

- Check valve dart

- Check valve dart spring

- Rigid valves

- Internal cylinder

- Piston case

- Piston

- Guide sleeve

- O ring

- Bit retainer ring

- Driver sub

Technical Parameters

| Parameter | Specifications | |

| Top sub connection | API 2-3/8 REG Pin | |

| Hammer length (W/O bit), mm | 990 | |

| Hammer OD, mm | Ø93 | |

| Weight (W/O bit), kg | 34 | |

| Wrench flat, mm | 75 | |

| Piston weight, kg | 7.1 | |

| Bit shank | DHD340A | |

| Bit size range, mm | 105-120 | |

| Recommended rotation speed, rpm | 25-40 | |

| Feed force, kg | 630-1100 | |

| Air consumption, m³/min | @10bar | 5.5 |

| @17bar | 9 | |

| @24bar | 14 | |

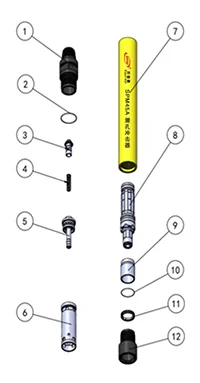

- Top sub

- Top sub with oring

- Check valve dart

- Check valve dart spring

- Rigid valves

- Internal cylinder

- Piston case

- Piston

- Guide sleeve

- O ring

- Bit retainer ring

- Driver sub

Technical Parameters

| Parameter | Specifications | |

| Top sub connection | API 2-3/8 REG Pin | |

| Hammer length (W/O bit), mm | 986 | |

| Hammer OD, mm | Ø99 | |

| Weight (W/O bit), kg | 39 | |

| Wrench flat, mm | 75 | |

| Piston weight, kg | 8.6 | |

| Bit shank | DHD340A | |

| Bit size range, mm | 115-130 | |

| Recommended rotation speed, rpm | 25-40 | |

| Feed force, kg | 690-1170 | |

| Air consumption, m³/min | @10bar | 6 |

| @17bar | 9.5 | |

| @24bar | 15 | |

- Top sub

- Top sub with oring

- Check valve dart

- Check valve dart spring

- Rigid valves

- Internal cylinder

- Piston case

- Piston

- Guide sleeve

- O ring

- Bit retainer ring

- Driver sub

Technical Parameters

| Parameter | Specifications | |

| Top sub connection | API 2-3/8 REG Pin | |

| Hammer length (W/O bit), mm | 1020 | |

| Hammer OD, mm | Ø126 | |

| Weight (W/O bit), kg | 70 | |

| Wrench flat, mm | 75 | |

| Piston weight, kg | 15 | |

| Bit shank | DHD350R | |

| Bit size range, mm | 138-152 | |

| Recommended rotation speed, rpm | 25-35 | |

| Feed force, kg | 830-1400 | |

| Air consumption, m³/min | @10bar | 7 |

| @17bar | 13.5 | |

| @24bar | 19 | |

- Top sub

- Top sub with oring

- Check valve dart

- Check valve dart spring

- Rigid valves

- Internal cylinder

- Piston case

- Piston

- Guide sleeve

- Bit retainer ring

- O ring

- Driver sub

Technical Parameters

| Parameter | Specifications | |

| Top sub connection | API 3-1/2 REG Pin | |

| Hammer length (W/O bit), mm | 1238 | |

| Hammer OD, mm | Ø148 | |

| Weight (W/O bit), kg | 108 | |

| Wrench flat, mm | 101 | |

| Piston weight, kg | 23.8 | |

| Bit shank | DHD360 | |

| Bit size range, mm | 165-194 | |

| Recommended rotation speed, rpm | 20-30 | |

| Feed force, kg | 990-1746 | |

| Air consumption, m³/min | @10bar | 9 |

| @17bar | 17 | |

| @24bar | 26 | |

- Top sub

- Top sub with oring

- Check valve dart

- Check valve dart spring

- Rigid valves

- Internal cylinder

- Piston case

- Piston

- Guide sleeve

- Bit retainer ring

- O ring

- Driver sub

Technical Parameters

| Parameter | Specifications | |

| Top sub connection | API 4-1/2 REG Pin | |

| Hammer length (W/O bit), mm | 1347 | |

| Hammer OD, mm | Ø182 | |

| Weight (W/O bit), kg | 178 | |

| Wrench flat, mm | 150 | |

| Piston weight, kg | 43 | |

| Bit shank | DHD380 | |

| Bit size range, mm | 203-305 | |

| Recommended rotation speed, rpm | 20-30 | |

| Feed force, kg | 990-1746 | |

| Air consumption, m³/min | @10bar | 11.5 |

| @17bar | 24 | |

| @24bar | 39 | |