SG Series DTH Hammer for Blast Hole Drilling

Down-the-hole hammers for blast hole drilling applications with high air pressureThe SG series hammers are a mining series of DTH hammers, widely used for drilling blast holes in mines, quarries, and road construction projects. They are also suitable for engineering holes in landslide protection, dam reinforcement, and anchoring, and perform excellently in geothermal, water well, and hydrological drilling applications.

- Efficient cuttings removal: Equipped with a strong blow system, all high-pressure air is used for cuttings removal, keeping the hole bottom clean. An adjustable air plug allows the air volume for cuttings removal to be tailored to rock characteristics, achieving optimal removal and improving drilling efficiency.

- Long service life: Hardened, wear-resistant outer sleeves can be reversed, extending replacement intervals and reducing operating costs.

- Stable performance: Fast action, high impact energy, and low air consumption enable efficient drilling in a wide range of complex rock conditions, improving construction efficiency and reducing energy usage.

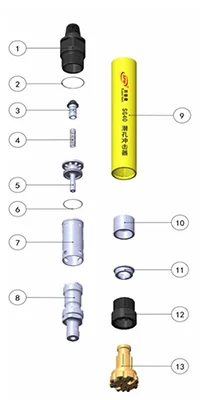

- Top Sub

- O-Ring

- Check Valve Dart

- Spring

- Distributor

- O-Ring

- Cylinder

- Piston

- Casing

- Bearing

- Bit retain ring ass

- Drive Sub

- Drill Bit

Technical Parameters

| Parameter | Specifications | |

| Top sub connection | API 2-3/8 REG | |

| Hammer length (W/O bit), mm | 737 | |

| Hammer OD, mm | Ø99 | |

| Hammer weight (W/O bit), kg | 32 | |

| Wrench flat, mm | 75 | |

| Piston weight, kg | 6.4 | |

| Bit shank | SG40 | |

| Bit size range, mm | 115-130 | |

| Recommended rotation speed, rpm | 25-40 | |

| Feed force, kg | 690-1170 | |

| Air consumption, m³/min | @10bar | 5.5 |

| @14bar | 6.9 | |

| @17bar | 8.8 | |

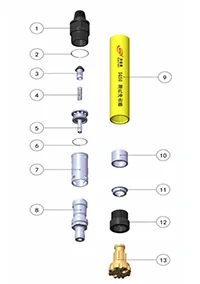

- Top Sub

- O-Ring

- Check Valve Dart

- Spring

- Distributor

- O-Ring

- Cylinder

- Piston

- Casing

- Bearing

- Bit retain ring ass

- Drive Sub

- Drill Bit

Technical Parameters

| Parameter | Specifications | |

| Top sub connection | API 2-3/8 REG | |

| Hammer length (W/O bit), mm | 970 | |

| Hammer OD, mm | Ø125 | |

| Hammer weight (W/O bit), kg | 64 | |

| Wrench flat, mm | 75 | |

| Piston weight, kg | 12 | |

| Bit shank | SG50 | |

| Bit size range, mm | 138-152 | |

| Recommended rotation speed, rpm | 25-40 | |

| Feed force, kg | 850-1400 | |

| Air consumption, m³/min | @10bar | 7.5 |

| @14bar | 9.5 | |

| @17bar | 11.5 | |