SPM-S Series DTH Hammer for Deep Hole Drilling

Down-the-hole hammers for deep hard rock drilling applications with high air pressureThe SPM S Series deep-hole DTH hammers are widely applicable and suitable for efficient drilling of tough rocks in hydrological water wells, geothermal wells, oil and gas wells, coalbed methane wells, and other engineering projects.

- Resistant to clogging: Testing and user feedback indicate a very low probability of blockage even when encountering water.

- High efficiency: Delivers large single-impact energy and high impact frequency, improving operational efficiency by over 15% compared to previous products.

- Long service life: Components are treated for fatigue resistance and corrosion protection, extending service life by approximately 20% over previous models.

- Reliable cuttings removal: Designed for deep-hole drilling, adjustable air intake ensures efficient removal of cuttings.

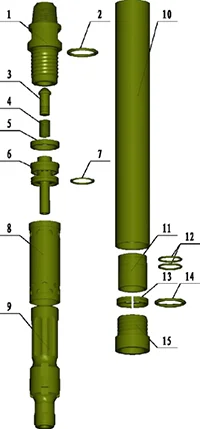

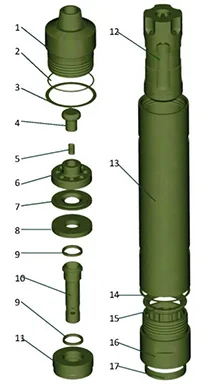

- Top sub

- Top sub with o-ring

- Check valve dart

- Check valve dart spring

- Rubber ring

- Rigid valves

- Rigid valve with o-ring

- Internal cylinder

- Piston

- Piston case

- Guide sleeve

- Guide sleeve with o-ring

- Bit retainer ring

- Bit retainer ring with o-ring

- Driver sub

Technical Parameters

| Drilling diameter, mm | Ø140-Ø152 |

| Hammer length, mm | 1143 |

| Hammer OD, mm | Ø125 |

| Weight, kg | 78 |

| Working pressure, MPa | 1.0-2.4 |

| Air consumption, m³/min | 7.5@1.0MPa;11.5@1.7MPa |

| Impact frequency, times/min | 840-1500 |

| Connection thread (to bit) | DHD350 |

| Connection thread (to drill pipe) | API 2 3/8' REG Pin |

| Compatible bit shank | SPMS50,SPM55A,DHD350 (without foot valve) |

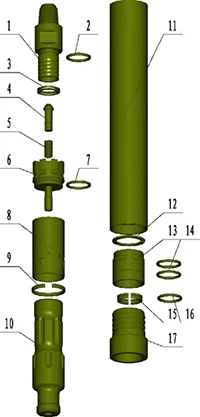

- Top sub

- Top sub with o-ring

- Compression ring

- Check valve dart

- Check valve dart spring

- Rigid valves

- Rigid valves with o-rings

- Internal cylinder

- Check ring

- Piston

- Piston case

- Circlip

- Guide sleeve

- Guide sleeve with o-ring

- Bit retainer ring

- Bit retainer ring with o-ring

- Driver sub

Technical Parameters

| Drilling diameter, mm | Ø165-Ø305 |

| Hammer length, mm | 1372 |

| Hammer OD, mm | Ø152 |

| Weight, kg | 92 |

| Working pressure, MPa | 1.0-2.1 |

| Air consumption, m³/min | 21.5@1.7MPa;32.5@2.4MPa |

| Connection thread (to bit) | DHD360 |

| Connection thread (to drill pipe) | API 3 1/2' REG Pin |

| Compatible bit shank | SPMS60,SPM65A,SPM360,DHD360 (without foot valve) |

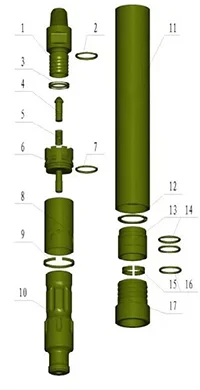

- Top sub

- Top sub with o-ring

- Compression ring

- Check valve dart

- Check valve dart spring

- Rigid valves

- Rigid valves with O-ring

- Internal cylinder

- Check ring

- Piston

- Piston case

- Circlip

- Guide sleeve

- Guide sleeve with o-ring

- Bit retainer ring

- Bit retainer ring with o-ring

- Driver sub

Technical Parameters

| Drilling diameter, mm | Ø203-Ø254 |

| Hammer length, mm | 1450 |

| Hammer OD, mm | Ø186 |

| Weight, kg | 215 |

| Working pressure, MPa | 0.8-3.0 |

| Air consumption, m³/min | 27.8@1.7MPa;36@2.4MPa |

| Connection thread (to bit) | DHD380 |

| Connection thread (to drill pipe) | API 4 1/2' REG Pin |

| Compatible bit shank | SPMS80,SPM380,SPM85A,DHD380 (without foot valve) |

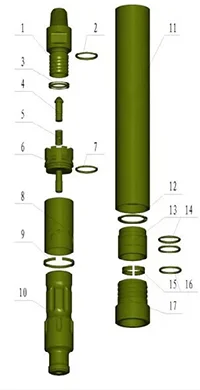

- Top sub

- Top sub with o-ring

- Compression ring

- Check valve dart

- Check valve dart spring

- Rigid valves

- Rigid valves with O-ring

- Internal cylinder

- Check ring

- Piston

- Piston case

- Circlip

- Guide sleeve

- Guide sleeve with o-ring

- Bit retainer ring

- Bit retainer ring with o-ring

- Driver sub

Technical Parameters

| Drilling diameter, mm | Ø251-Ø381 |

| Hammer length, mm | 1552 |

| Hammer OD, mm | Ø229 |

| Weight, kg | 350 |

| Working pressure, MPa | 1.0-3.0 |

| Air consumption, m³/min | 45.4@1.7MPa;67.9@2.4MPa |

| Connection thread (to bit) | S100 |

| Connection thread (to drill pipe) | API 5 1/2' REG Pin |

| Compatible bit shank | SPM-S100 |

- Top sub

- Top sub with o-ring

- Steel pad ring

- Adjusting pad

- Compression ring

- Check valve dart

- Feed tube retainer pin

- Check valve dart spring

- Rigid valves

- Rigid valves with o-ring

- Internal cylinder

- Check ring

- Piston

- Piston case

- Rubber ring

- Guide sleeve

- Bit retainer ring

- Bit retainer ring with o-ring

- Driver sub

- Driver sub with o-ring

- Rubber ring

- Retainer

Technical Parameters

| Drilling diameter, mm | Ø311-Ø508 |

| Hammer length, mm | 2110 |

| Hammer OD, mm | Ø275 |

| Weight, kg | 670 |

| Working pressure, MPa | 1.0-3.0 |

| Air consumption, m³/min | 54@1.7MPa;78@2.4MPa |

| Connection thread (to bit) | S112A |

| Connection thread (to drill pipe) | API 7 5/8' REG Pin |

| Compatible bit shank | SPM112A |

- Backhead

- Backhead O-ring

- Breakout washer

- Check valve

- Spring

- Valve cover

- Buffer cover

- Compression buffer

- Tube buffer

- Control tube

- Tube holder

- Piston

- Piston case

- Breakout washer

- Bit retaining ring

- Chuck

- Chuck bearing

Technical Parameters

| Drilling diameter, mm | Ø457-Ø660 |

| Hammer length, mm | 2190 |

| Hammer OD, mm | Ø406 |

| Weight, kg | 1450 |

| Working pressure, MPa | 1.0-2.4 |

| Air consumption, m³/min | 74@1.7MPa;90@2.0MPa |

| Connection thread (to bit) | N180 |

| Connection thread (to drill pipe) | API 8 5/8' REG Pin |

| Compatible bit shank | SPM-S180,N180 |